PROJECT TIME:

LOCATION:

PRODUCT:

CLIENT:

OWNER:

ARCHITECT & DESIGNER:

2018

300 Charoen Krung Road, Bangkok, Thailand

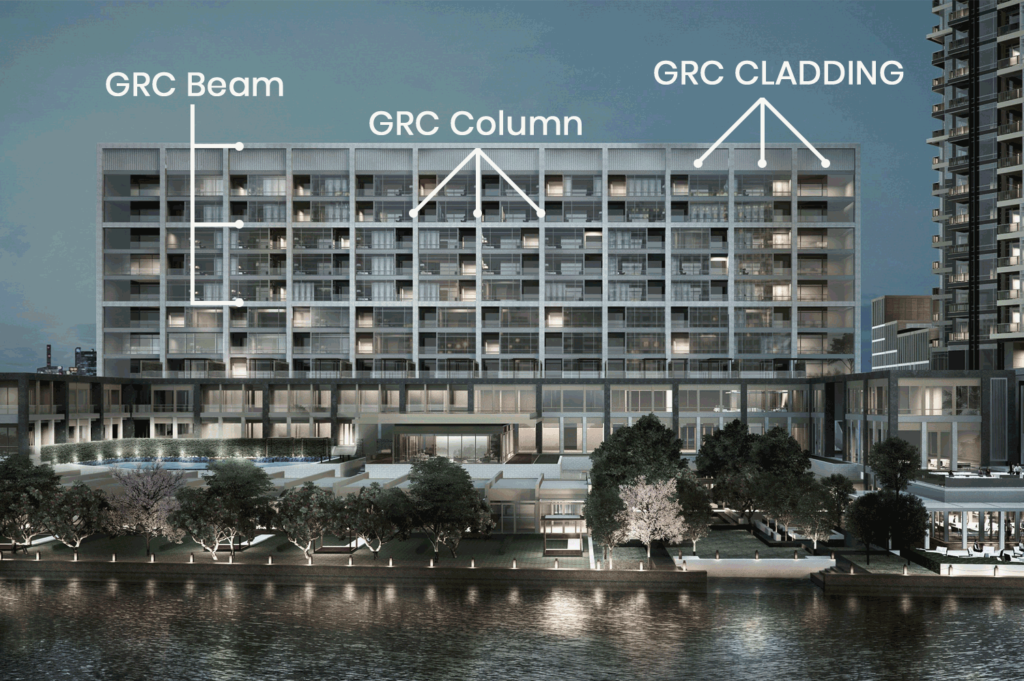

CLADDING – DESIGN & SUPPLY – Bright white sparkle GRC Cladding for column & beam

BCEG Thai International Co. Ltd.

Country Group Development PCL

Hamilton International, Malaysia

Cladding

There are two sections of Cladding: a white sparkle for column and beam and a beige wave texture panels to cover lightweight block wall.

The project demanded a high-quality white concrete finish with the self-cleaning property. GRC (Thailand) proposed to use an advance high-performance concrete formulation of a sparkling skim coat with self-cleaning capability, matte and texture finish, yet easy to clean and with a ten years’ warranty durable water resistance surface using Guard Industries easy to clean water repellent penetrative-clear protection.

Design

We use white cladding to cover all the beam, columns and section of the balcony. The building is 12 floors 50m High, 108m wide and 10m breadth. There are approximately 3700sq.m of white cladding.

The design of column cladding fit into each other to enable easy installation and alignment during installation. The fitted hot-dip galvanized frame with 304 stainless steel flex anchors are set and secured to the GRC cladding in the factory. Only 2-4 fixing bolts secure each panel.

The east side of the building also has full-length groove cladding in beige colour. These start from level three to the top of the building and has to pass through two levels of GRC beam and go across the building. The cladding is solid concrete colour and treated with Guard Industry coating.

This project showed that the concrete finish is not only possible but attractive and durable for cladding use. The natural concrete finish will also have less problem in the future when compared with natural stone/tile cladding and painting.

The pictures showed GRC installation at 80% completion.

Installation

The next piece of the column fits on one end of the already installed column. There should be no opening for installation unless it’s necessary since any patching and fixing is hard to hide and will require skill and time. It is very different from the panel that will receive a coating after the finish to patch and cover the repair. Care is taken in every step to prevent the surface finish of the GRC from dirt and damage.

The cladding design allows easy installation and requires little modification on-site except for the area constructed outside tolerance. Delay by others affects the GRC installation by more than five months. And the most damage is products installed damage by the worker in following up work, particularly at balcony and ground floor area where goods carry by hand or machine, dirty hand, paint causing minor damage and discolourations of the white surface. And during installation, heavy grease rain down from the tall Four Seasons Residence next door landed on the top of the horizontal beam cladding also required additional cleaning.

An increased cladding added at the rooftop on the riverside. Three interlock panels will cover one section, and all the panels are pre-coated with exterior wall paint specify by the customer before installation. Touch up, in this case, is necessary after installation.

With the high production capacity of up to 1000sq.m per day, GRC (Thailand) effortlessly added this additional work to the project and completed from mould making to installation within 30 days.

Versatile GRC

This project shown that concrete finish not only possible, but attractive and durable for cladding use. Natural concrete finish will also have less problem in the future when compare with natural stone/tile cladding, and painting.

The future of Glassfiber Reinforced Products in Asia is very much dependent on the experience, knowledge and integrity of the manufacturer to produce a consistent and cost-effective quality product. To know if your supplier possesses these qualities, the buyer, the specifier and the consultant must have profound knowledge in GRC or have competent professional/consultant to specify the need of each GRC project to ensure proper method, product design, manufacturing and installation. For any information on the designing, choosing and evaluating of GRC, please feel free to contact us.

Quality Alkaline Resistance Glass Fiber Reinforced Concrete by GRC (Thailand)

Your reliable partner in every project

Be Creative with Concrete.

TAKHINTIA 29, TAKHIANTIA, BAN LAMUNG, CHONBURI 20150 THAILAND

Quick Menu

© 2020 GRC Thailand. All Rights Reserved.